Surely waterparks and chemical processing plants couldn’t have anything in common, right? Not so fast. Waterparks and chemical plants are more similar than you might think. So, what do waterparks and chemical processing plants have in common? Corrosion Issues!

What Causes Corrosion?

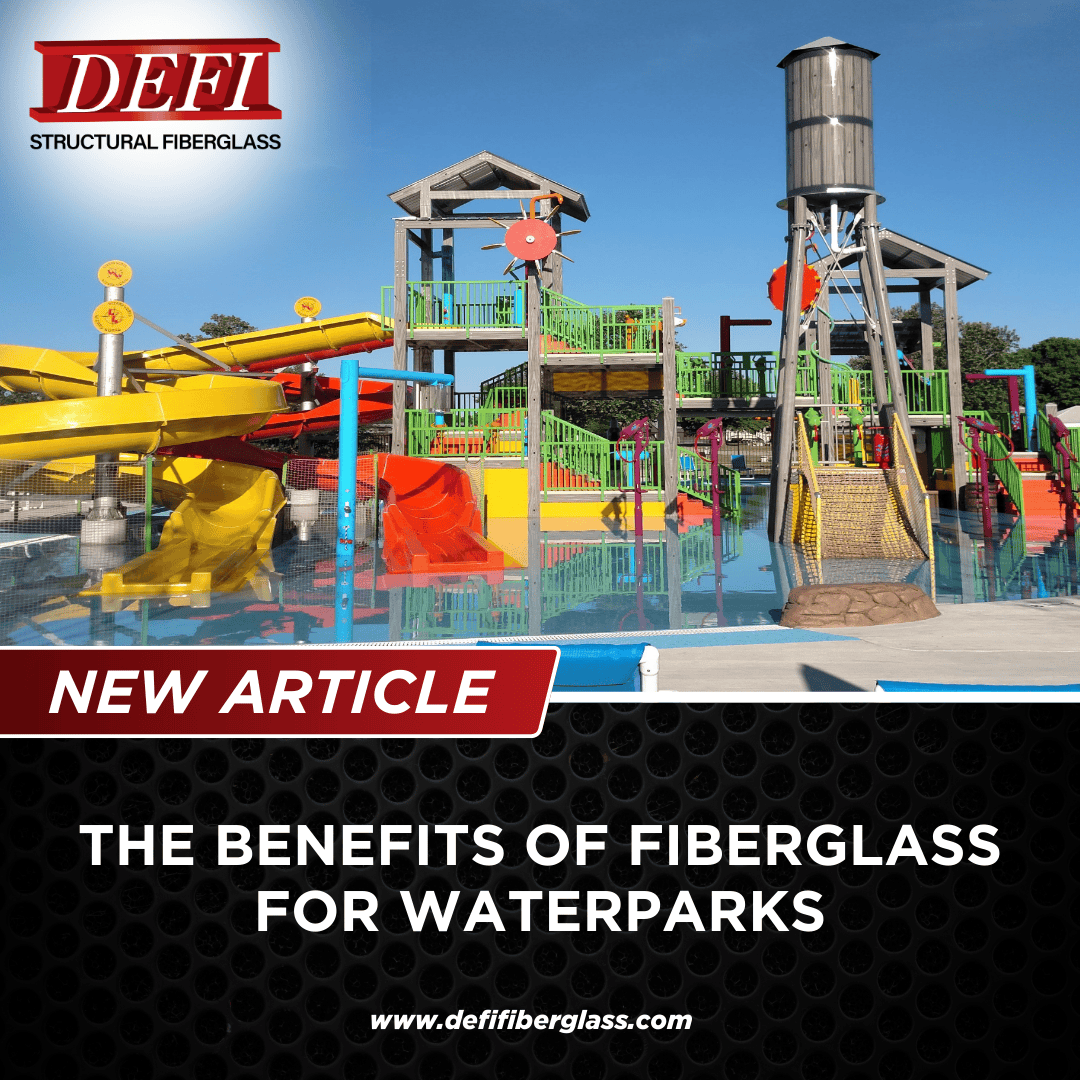

Waterparks attract millions of visitors each summer. In fact, over one million people visited Schlitterbahn in New Braunfels alone in the summer of 2016. Think about it, the reason that waterparks are so attractive is that the water provides an escape from the unbearable heat.

So, with millions of people visiting waterparks each year, the water needs to be purified with large amounts of chlorine. This is where the corrosion comes in to play. Lots of chlorine equals lots of corrosion. Now, what’s the solution? We’re glad you asked.

What’s the Solution?

D.E.F.I. Structural Fiberglass is an expert when it comes to applying the benefits of structural fiberglass to a variety of waterpark applications. D.E.F.I.’s fiberglass grating is commonly used in waterparks as walking surfaces and water inlet/outlet screens. In addition to these uses, our high-quality grating comes with a pool grit anti-skid surface that is extremely soft to the bare feet of waterpark visitors. D.E.F.I. also has extremely high-quality VGBA approved grating.

Thought we already exhausted the possible uses of fiberglass grating in waterparks? Not even close. D.E.F.I. has a full array of FRP stair towers and egress towers that are 1/3 the weight of steel and half the cost of stainless steel.

Needless to say, our structural fiberglass can meet a wide range of waterpark needs. Call D.E.F.I. Structural Fiberglass today to see how we can assist you with your waterpark corrosion issues.