When it comes to cost effective materials for the industrial workplace, nothing can compare to the savings that structural fiberglass fabrication delivers. When compared side by side, fiberglass molded into the same structures as steel or aluminum is lighter, resistant to corrosion, and just as strong but at a fraction of the price. These and other qualities of FRP (fiber reinforced plastic) products barely scratch the surface of the many benefits that this innovative class of products offers.

THE VERSATILE BENEFITS OF WORKPLACE FIBERGLASS

Just as with steel and aluminum, there are many different grades of FRP products that carry specific traits for specific environments and uses. Even though their traits are different they all possess the following general characteristics that give them the advantage over traditional materials:

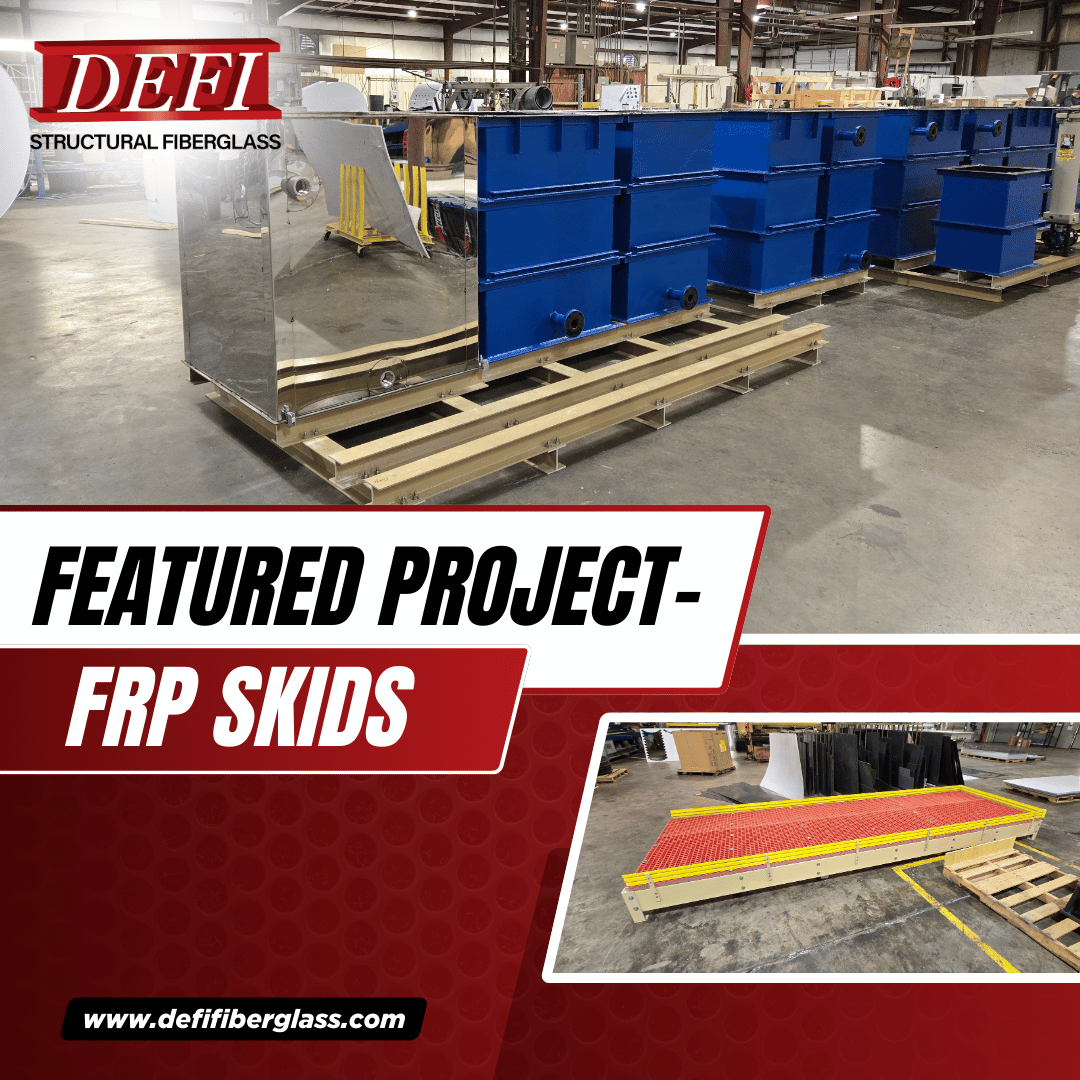

- Fabrication and Installation – Due to the nature of the materials that are used to create FRP, fabrication and design can be very flexible. FRP for a construction site for example can be fabricated on site using basic tools of carpentry and some carbon or diamond tip blades. The light weight of FRP allows for it to be transported and installed easily with no welding tools. Unlike steel, FRP products do not need special equipment and considerations to design and install.

- Resilience – Fiberglass molded products are finished with a hard gel coat which can come in many colors and variable degrees of hardness to give it more resilience. This gel coat can offer many benefits such as added corrosion resistance, increased traction, and other industry specific needs.

- Cost – Stainless steel does have a lower initial material cost but, without taking installation and maintenance costs into consideration, that can be very misleading. Wood is less expensive but far less resilient and durable. Aluminum, while comparable in price, also has an overall higher cost, just like steel, when you factor in maintenance and installation costs. The bottom line is – fiberglass has a much lower overall cost than steel and aluminum.

- Stiffness – FRP products also boast an extreme stiffness that other materials just can’t duplicate. Up to 3 times more rigid than wood, fiberglass does not bend to deformation at maximum workload. Its impact resistance is also remarkable as it does not deform or break like wood, aluminum, or steel do when impacted.

- Corrosion, Rot & Termite Resistance – Steel rusts, Aluminum is reactive, Wood rots and is susceptible to termites but FRP is corrosion resistant to the effects of water, corrosive chemicals and insects. In addition, steel requires additional costs for galvanizing or painting in order to be used in some environments—adding to its overall cost. Whether it’s chemical exposure, salt water exposure, or extreme conditions, FRP products will outperform traditional materials every time.

- Flexural Strength – FRP products have a greater flexural threshold than wood and, when it comes to terms of strength to weight ratio, fiberglass is stronger than both aluminum and steel.

- Weight – Coming in at ⅔ the weight of aluminum and just ¼ the weight of steel, fiberglass is much easier to install and repair, from a logistics standpoint, which cuts maintenance costs considerably.

- Color – Fiberglass molded structures can have pigments added to them during fabrication making the color through and through rather than painted on like traditional materials. Fiberglass only needs to be painted if it is going to be constantly exposed to direct sunlight.

- Thermal Characteristics – FRP has outstanding performance as an insulator that has little thermal conductivity. Where metal and steel conduct heat, which can be dangerous in the workplace, fiberglass remains cool regardless of the surroundings.

- Electrical Conductivity – Since FRP is non-conductive it does not need to be grounded and can be used in places where high-voltage is a hazard, such as power plants.

- Signal Interference – Unlike metal, fiberglass does not interfere with radio waves or any electrical signals for that matter. This means it can be used in environments where metal would normally interfere, causing potential safety hazards.

As you can see, the workplace benefits of FRP products make it a preferable alternative to more expensive and logistically inefficient materials, such as steel and aluminum. If you think a bit more outside the box you will find that Fiberglass molded products also help your company remain compliant to building and safety codes.

THE CODE COMPLIANCY FACTOR

When it comes to building structures as well as public installations, structures and surfaces must meet stringent codes and remain in compliance for the life of the structure. Whether it’s compliance to fire codes, stability requirements, ADA compliance, or other building codes— fiberglass, due to its composition, can be adapted easily to be compliant at a lower cost than traditional materials. Take for example two of the most common products needed to meet two of the most common building requirements— fire and ADA code compliance:

Fire Code Compliance

DEFI Phenolic FRP grating is a product designed to be the most reliable material for safety and durability during a fire. Because of its non-flammable trait, it is able to hold up to direct exposure to fire for an extended duration without compromising major structural integrity. This remarkable durability is due to structural fiberglass fabrication with flame retardant phenolic resin.

DEFI Phenolic Gratings satisfy and exceed the L2 performance metric requirements to be used in open platform areas where evacuees are most likely to assemble en masse during an incident, such as a fire or lifeboat launch areas in marine fire situations.

Benefits of Phenolic Fiberglass:

- Very Low Smoke Index

- Low Toxic Fume Emissions

- Up to 300°F Temperature Resistance

- High Corrosion Resistance

- Very Low Maintenance

ADA Code Compliance

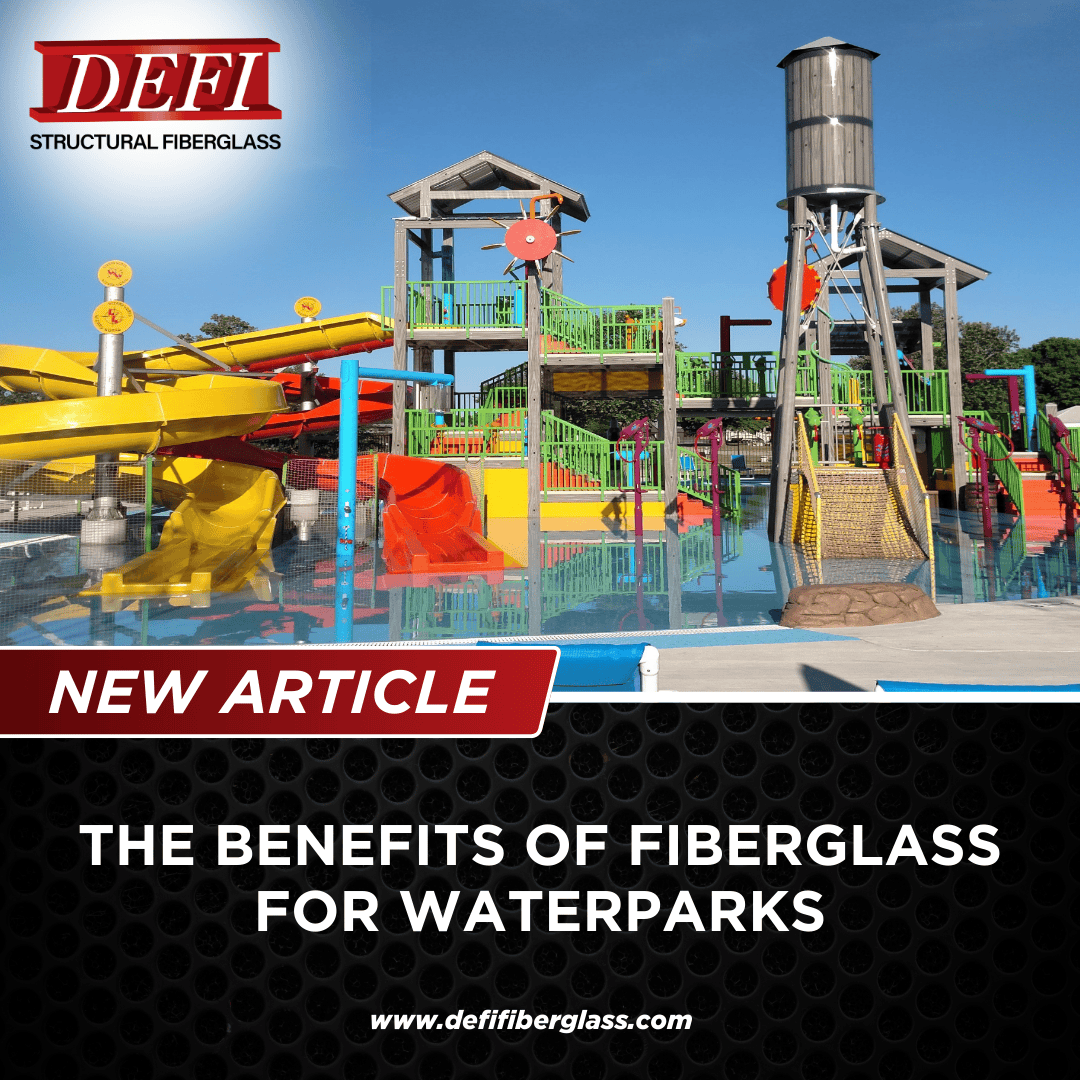

DEFI ADA compliant fiberglass grating offers the same durable benefits as our standard gratings and can be combined with any of our resins to add additional compliance, such as flame resistant properties. The mesh patterns of these gratings are designed in such a way to safely facilitate high pedestrian traffic including those with high heels or canes, crutches, and walkers. The small mesh of our ADA compliant grating also allows for comfortable foot traffic where pedestrians might be barefoot, such as waterparks and public pools.

FIBERGLASS IS THE FUTURE

Fiberglass is increasingly being used to replace less efficient and more costly materials every day. As companies begin to see the major impact on safety, operational costs, and liability that fiberglass offers, it is being implemented in every possible area of the workplace. When you need the best fiberglass grating Houston businesses have trusted for decades, call DEFI and speak with one of our consultants.