FRP Generator Platforms:

Why FRP is the Smart Choice for

Data Centers

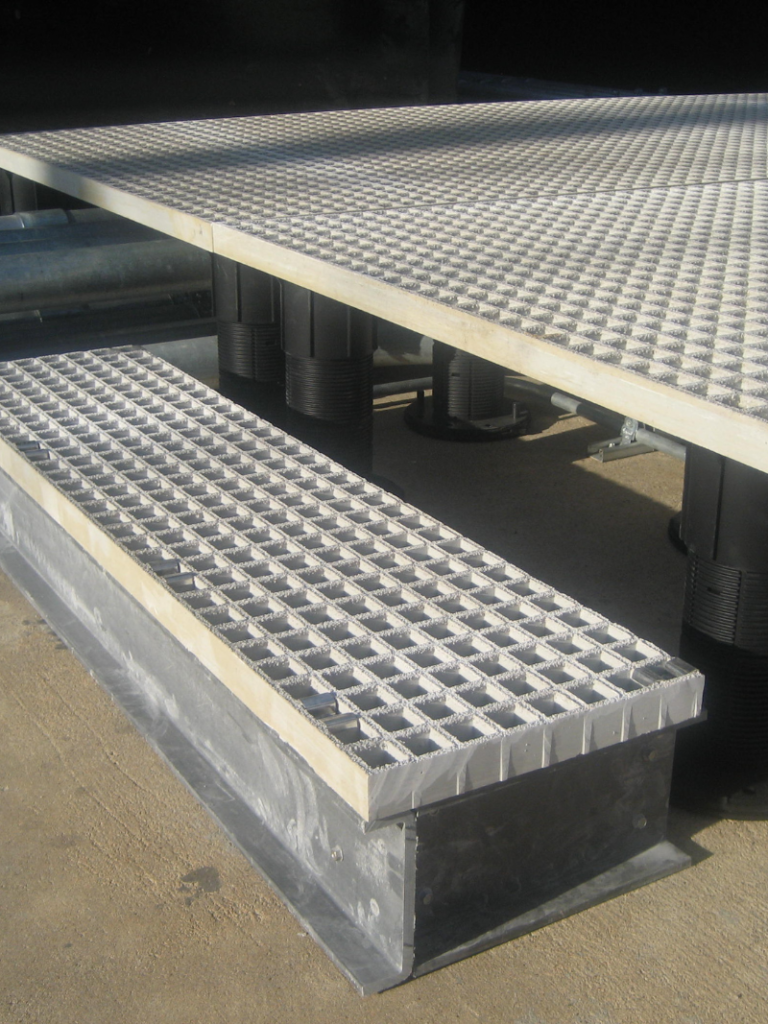

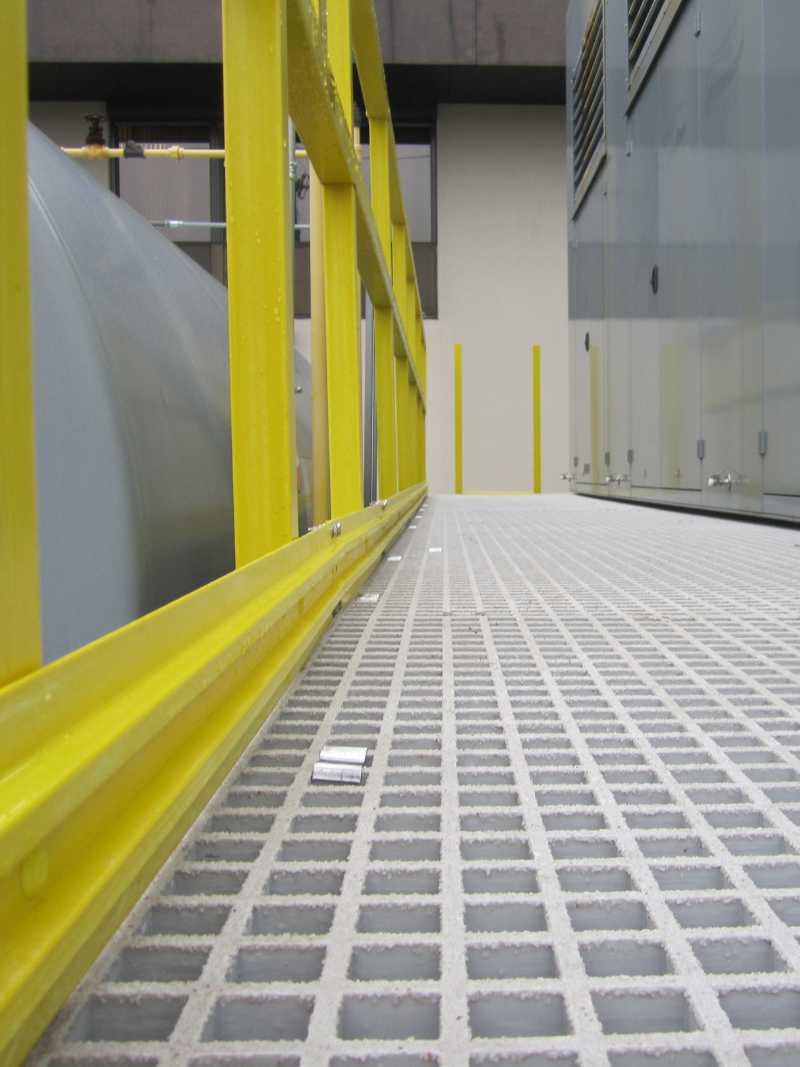

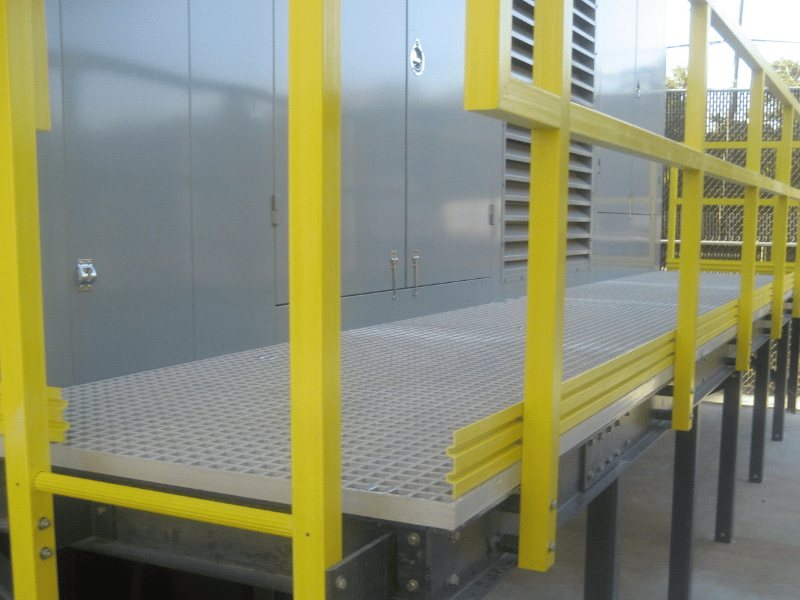

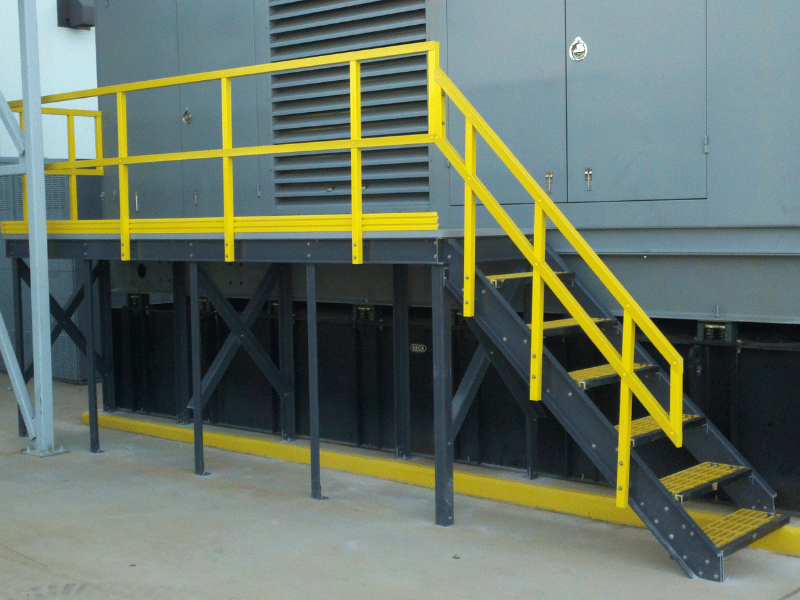

When it comes to generator platforms (Gen Sets) for data centers, you need a lightweight, safe material. FRP and Fiberglass deliver all this and much more. Weighing just ⅓ as much as steel, FRP is easier to handle and takes only half the time to install. Unlike steel, FRP platforms are non-conductive, corrosion-resistant, and reduce installation costs.

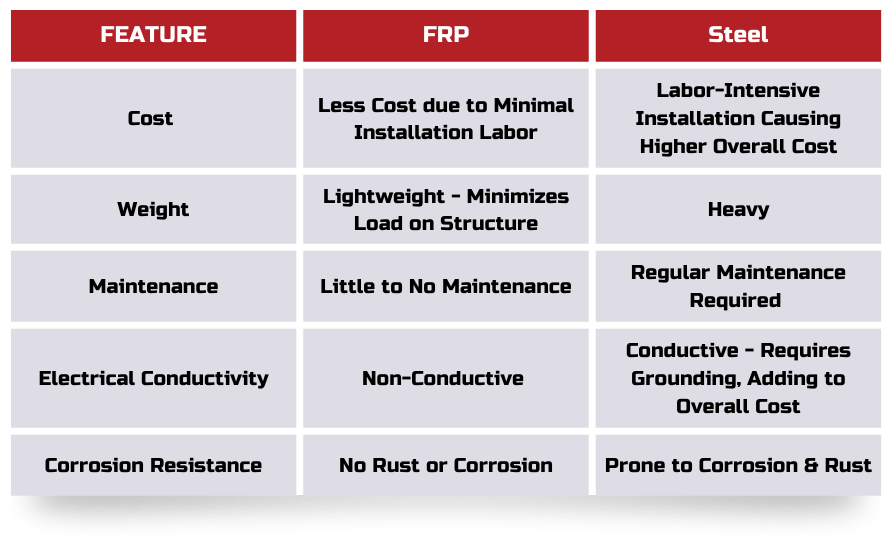

FRP Platforms for Data Center Generators vs. Steel

Choosing the right material for your data center’s Gen Sets is crucial for ensuring effective operations, minimizing installation and maintenance costs, and maximizing ROI. FRP Gen Sets are the lightweight, cost-effective alternative to steel, making them the smarter investment for your data center.

Durability & Longevity

Corrosion Resistant: Your FRP Gen Sets will last as long as your generators do. Unlike steel, FRP and fiberglass are naturally corrosion resistant, making it the perfect material for outdoor applications. FRP doesn’t contain iron like other materials that are prone to oxidation and rusting. The resin used to create FRP does not react with chemicals, ensuring that your data center’s platforms stay stable and intact.

UV Stable: FRP is UV damage resistant, creating a generator platform that won’t fade or crack. This is extremely important for outdoor applications and helps retain the structural integrity of the platforms.

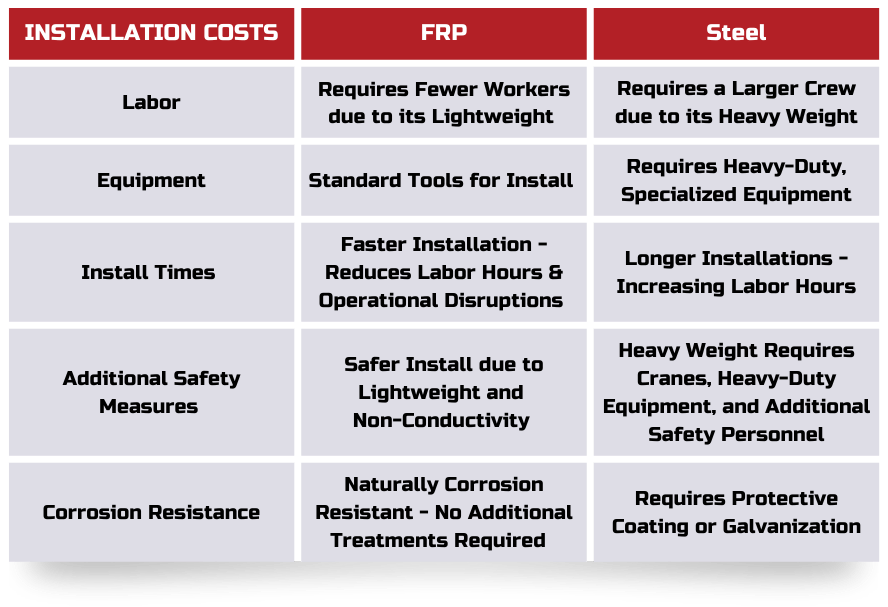

Gen Sets Installation Costs: FRP vs. Steel

For maximum benefits, reduced installation costs, and enhanced safety, FRP consistently outperforms steel. The advantages of FRP make it easier and safer to install, while steel requires more resources at every step. When you use FRP for data center Gen Sets, you save time and money on the installation as well as long-term maintenance.

FRP Easy Installation

Because FRP is lightweight, it makes installation quicker, easier, and more cost-effective compared to steel. Using FRP significantly reduces overall installation costs. FRP installations do not require permits, cranes, or welding and can be completed using standard tools. This not only saves you money, but also reduces installation times.