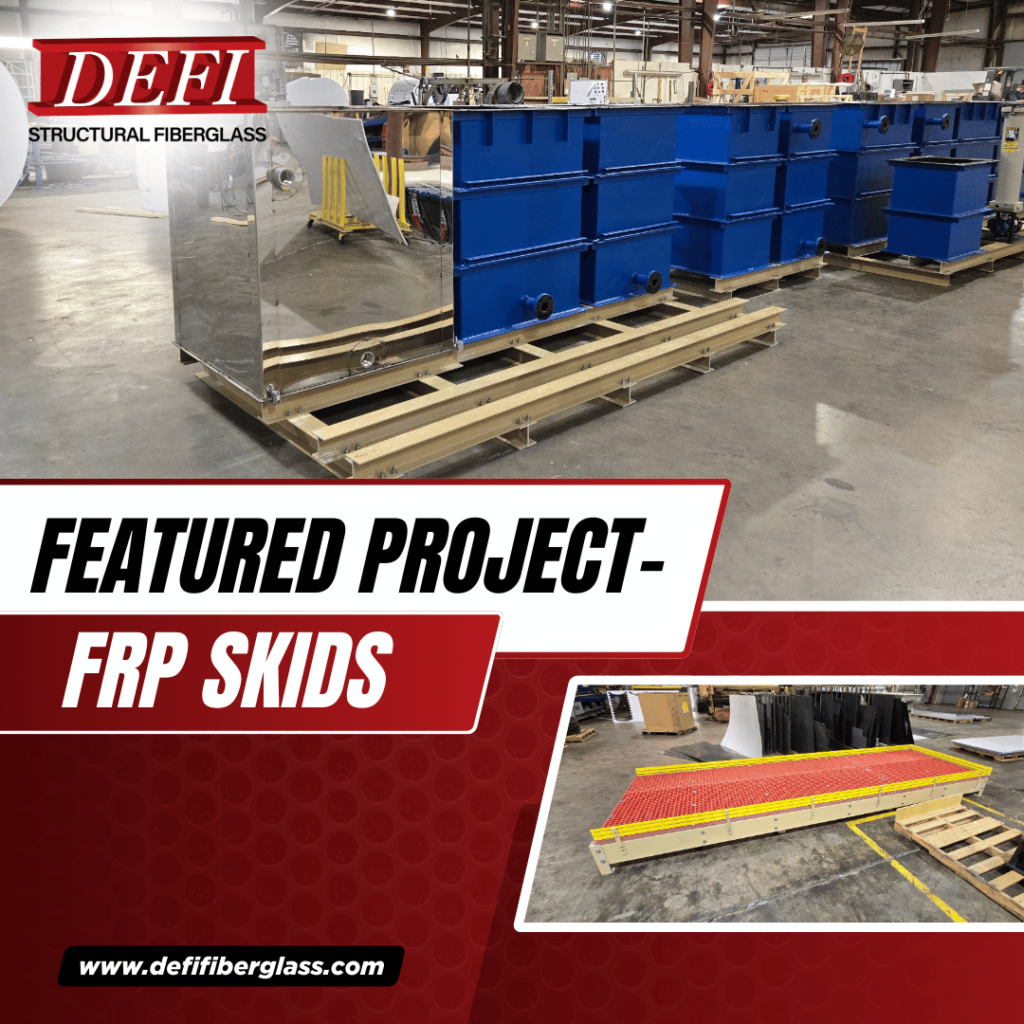

Skids are industrial platforms that are used in many industrial and commercial applications. FRP skids in a galvanizing facility serve many key functions such as providing support for equipment, creating easy mobility and movement for heavy machinery, and maintaining proper equipment alignment. They are also used to lift and keep equipment off the ground. These structures enhance safety and help streamline operations in these facilities.

FRP Benefits for Industrial Applications

Fiber reinforced plastic (FRP) is a great choice for skids. FRP provides the strength, durability, and non-corrosive properties that are required for skids in this industry. This is a low-maintenance material so it helps reduce the cost of operations. Along with being non-corrosive, FRP is also resistant to chemicals, making it perfect for applications like this where chemicals are used for the galvanization process and treatments.

Specifics About this Project

Our client, a galvanizing facility, needed five customized FRP skids that could withstand a highly corrosive environment. Our team completed this task by adding a vinyl ester resin to enhance the anti-corrosive and durable properties of fiberglass, allowing the product to hold up against harsh environments. To increase the strength of the skids, we included wide flange beams. This helps the FRP skids support heavy loads. We used angle and FRP molding grating to increase slip resistance and make the FRP skids ideal for this application.

FRP Benefits for Industrial Applications

Fiber reinforced plastic (FRP) is a great choice for skids. FRP provides the strength, durability, and non-corrosive properties that are required for skids in this industry. This is a low-maintenance material so it helps reduce the cost of operations. Along with being non-corrosive, FRP is also resistant to chemicals, making it perfect for applications like this where chemicals are used for the galvanization process and treatments.

Specifics About this Project

Our client, a galvanizing facility, needed five customized FRP skids that could withstand a highly corrosive environment. Our team completed this task by adding a vinyl ester resin to enhance the anti-corrosive and durable properties of fiberglass, allowing the product to hold up against harsh environments. To increase the strength of the skids, we included wide flange beams. This helps the FRP skids support heavy loads. We used angle and FRP molding grating to increase slip resistance and make the FRP skids ideal for this application.

Why to Choose DEFI for FRP Skids?

For this project, we were able to produce the five FRP skids ready for installation to our client in three weeks from concept to finished product. The skids were fully assembled in our shop and shipped ready to go. We created a design for our client that was to their precise specifications and needs. When it comes to creating equipment support and structural framework for industrial facilities, FRP structures can be completely tailored to the size and dimensions of the space.

FRP skids are just one example of how FRP can be used in the industrial world. Fiberglass and FRP are excellent for many industrial applications because of the host of benefits it offers. This versatile, lightweight material can be tailored to exactly what your company needs and lasts longer than many traditional materials such as steel. To learn more about fiberglass and FRP, contact us through our website here or check out our resources page here.

Follow us on LinkedIn!