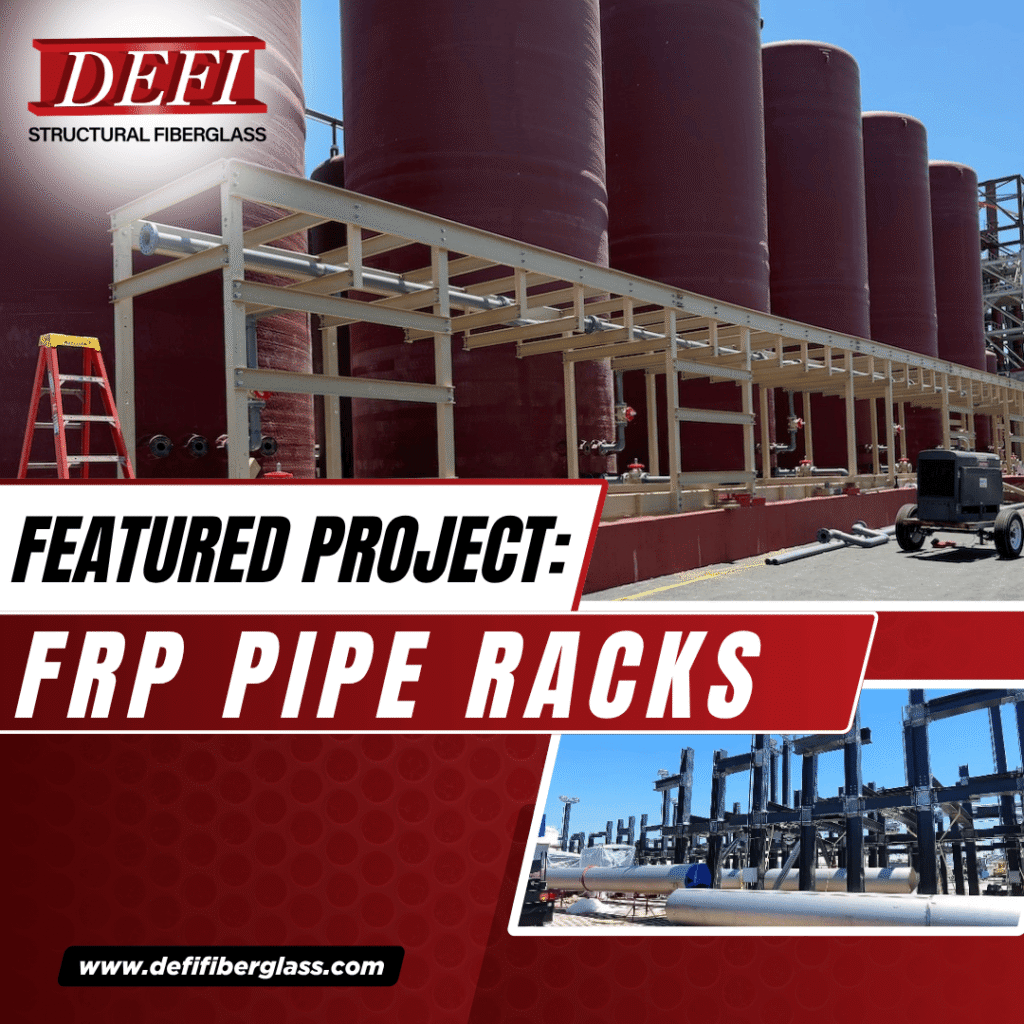

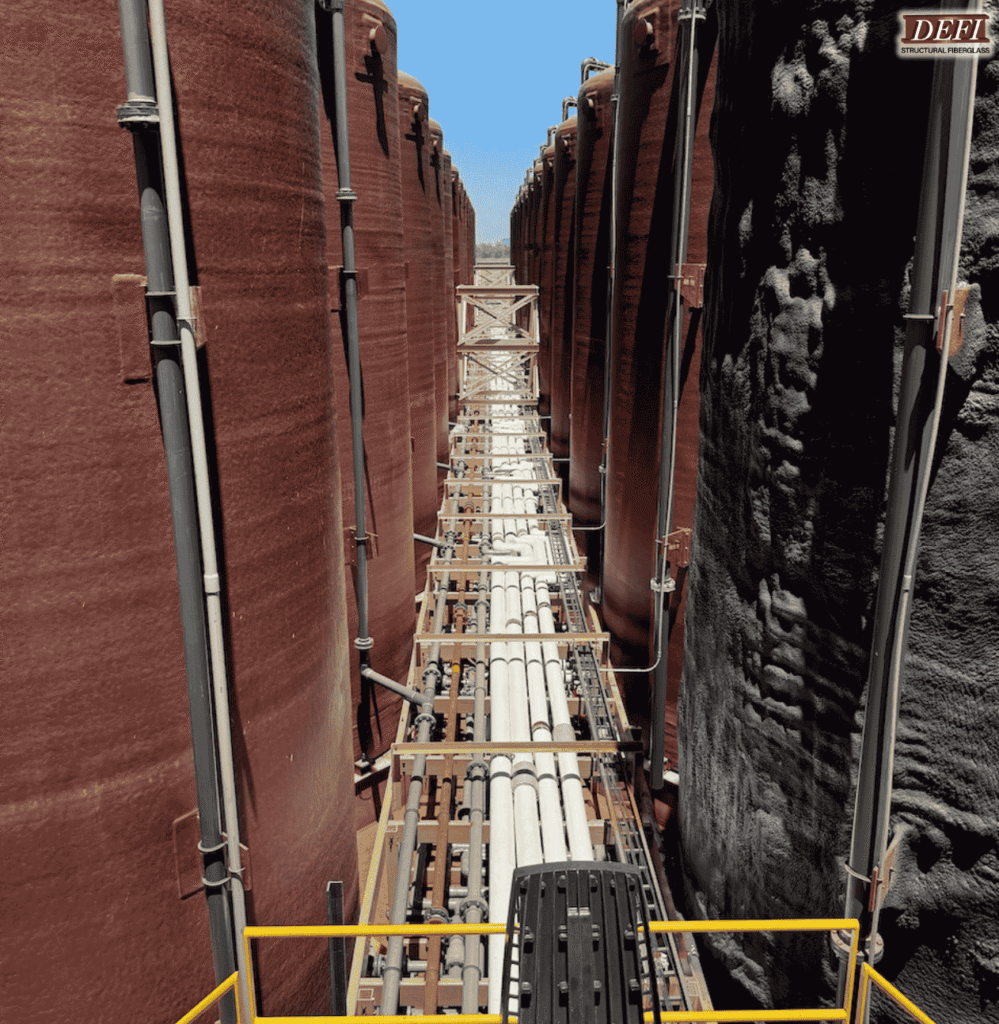

FRP pipe racks are essential components to support and elevate pipes and keep the work area safe. Pipe racks in industrial settings like the oil and gas industry, chemical plants, and water treatment facilities have traditionally been constructed from steel. While steel does offer high load-bearing strength, steel requires a protective coating to prevent degradation and corrosion, especially in coastal regions and areas that are exposed to chemicals. Alternatively, FRP (Fiber Reinforced Polymer) is inherently non-corrosive and offers a higher strength-to-weight ratio. While steel is the traditional material used, FRP is quickly gaining popularity in these types of applications.

Project Overview

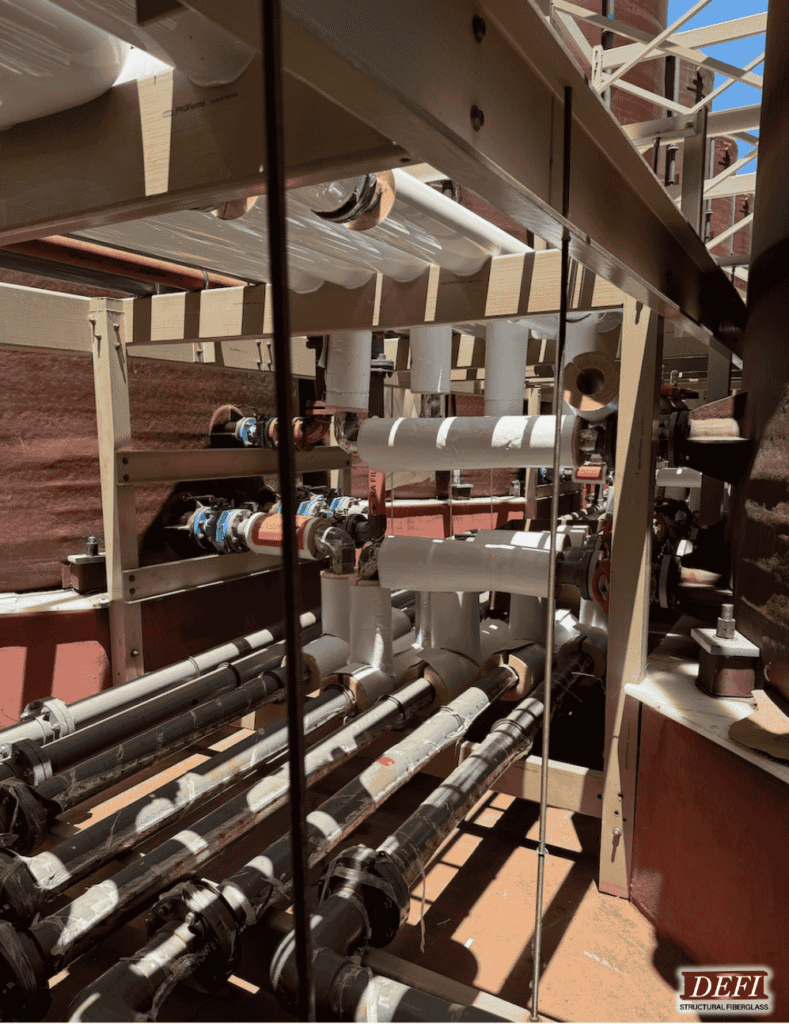

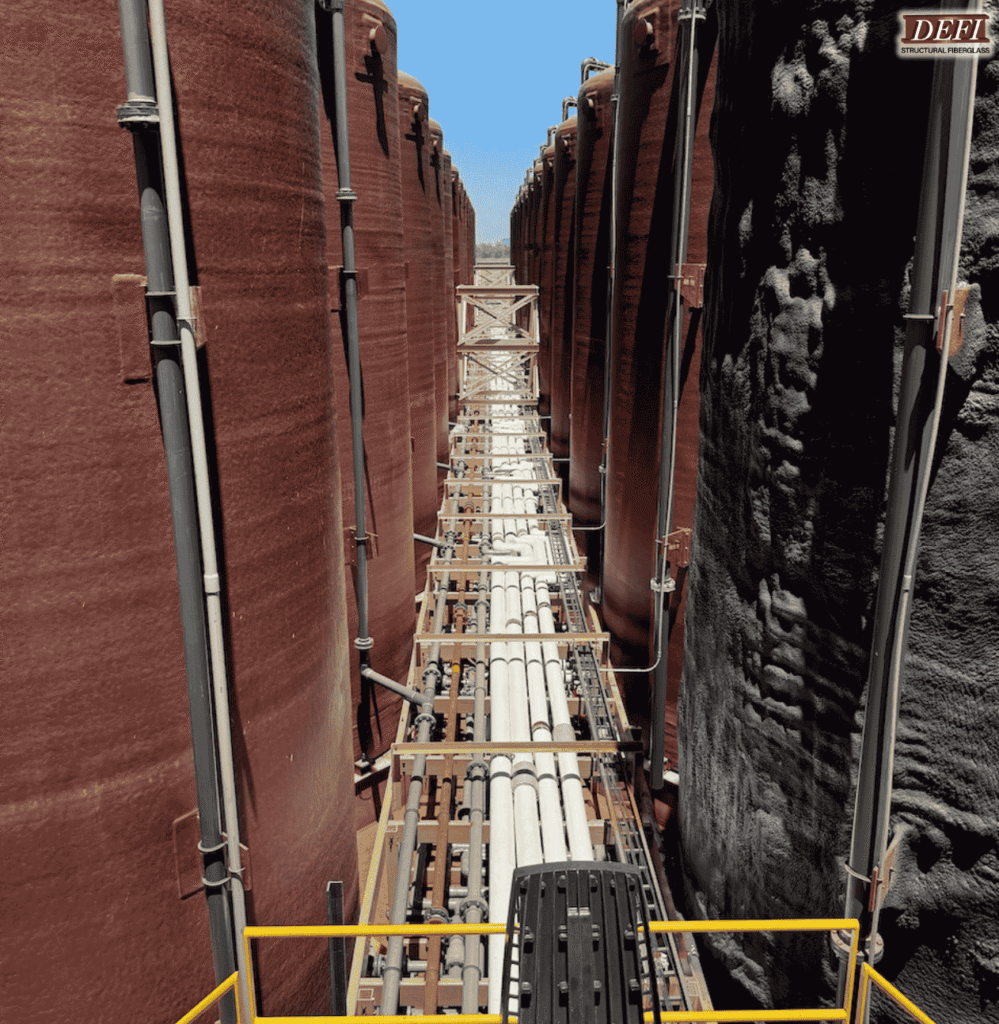

A Petrochemical facility needed pipe racks installed. Because FRP offers so many benefits, the client chose FRP as the building material. Our team at DEFI Fiberglass designed custom pipe racks to fit the exact specifications of the project using angle, wide flange beams, channels, and I-beam pultruded FRP shapes.

FRP in Harsh Environments

FRP is a mix of fiberglass and resin. The polyester or vinyl resin holds the fibers together. The type of resin used depends on the application and the needs of the project. The combination of fiberglass and resin creates a strong, corrosion-resistant building material, making it ideal for industrial and corrosive environments.

FRP is resistant to:

- Saltwater

- Acids

- Chemicals

- UV Damage

- Extreme Weather

- Extreme Heat

- Impacts and Wear & Tear

Maintenance-Free FRP Pipe Racks

FRP is inherently corrosion resistant, so it won’t rust or rot. There isn’t a need for protective coatings or treatments that have to be reapplied over time. This makes FRP virtually maintenance-free, which lowers repair and maintenance costs and reduces disruptions to workflow.

Project Overview

A Petrochemical facility needed pipe racks installed. Because FRP offers so many benefits, the client chose FRP as the building material. Our team at DEFI Fiberglass designed custom pipe racks to fit the exact specifications of the project using angle, wide flange beams, channels, and I-beam pultruded FRP shapes.

FRP in Harsh Environments

FRP is a mix of fiberglass and resin. The polyester or vinyl resin holds the fibers together. The type of resin used depends on the application and the needs of the project. The combination of fiberglass and resin creates a strong, corrosion-resistant building material, making it ideal for industrial and corrosive environments.

FRP is resistant to:

- Saltwater

- Acids

- Chemicals

- UV Damage

- Extreme Weather

- Extreme Heat

- Impacts and Wear & Tear

Maintenance-Free FRP Pipe Racks

FRP is inherently corrosion resistant, so it won’t rust or rot. There isn’t a need for protective coatings or treatments that have to be reapplied over time. This makes FRP virtually maintenance-free, which lowers repair and maintenance costs and reduces disruptions to workflow.

Easy Installation

Because FRP is a lightweight material, it makes installation easier than metal building materials. FRP is ⅓ lighter than steel, so it doesn’t require special permits or heavy-duty equipment. Oftentimes, steel requires cranes and safety personnel for the installation, driving up the cost. These FRP pipe racks are installed faster, safer, and cheaper than steel pipe racks.

This FRP pipe racks project is a great example of why FRP is the smart alternative to steel and other traditional materials. FRP is a strong, durable material that will stand the test of time, even in the harshest conditions.

Our team can create customized fiberglass structures to fit your exact specifications. Contact us today to discuss your project and find the perfect solution for your needs.

Check out our resources page here.

Follow us on LinkedIn!