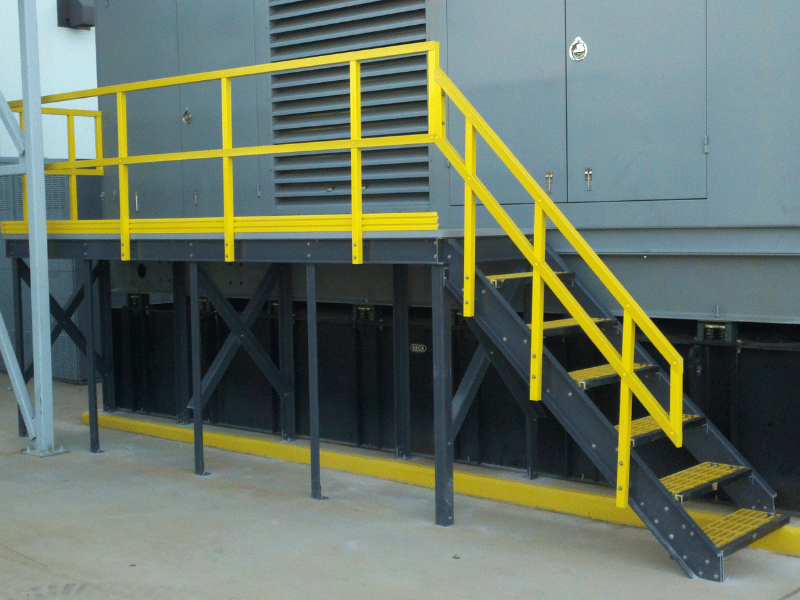

Data centers use generators for backup power and to ensure continuous operation. Data Center Generator Platforms (gen sets) are used to elevate the generators to prevent overheating and provide a platform for maintenance crews working on the generators. Due to its strength, steel is traditionally used for projects like this, but FRP is a better alternative because of its added benefits.

So which is the better material? When choosing the material for data center generator platforms, there are key factors to consider like cost, durability, and maintenance. Let’s take a look at how the materials compare.

Data Center Generator Platforms: FRP & Fiberglass VS. Steel

Cost – When looking at just the comparison of materials, steel has a lower upfront cost, but there are many hidden costs associated with the installation and maintenance of steel. FRP has a significantly lower installation cost due to its lightweight, which reduces its labor and equipment needs when compared to steel.

Weight – There’s no doubt that steel is heavy. In fact, it can weigh up to 75% more than FRP. This means special equipment, special tools, and more labor. Often, special safety personnel have to be hired when installing steel. FRP on the other hand is lightweight, easy to install, and only requires normal tools.

FRP & Fiberglass VS. Steel

Cost – When looking at just the comparison of materials, steel has a lower upfront cost, but there are many hidden costs associated with the installation and maintenance of steel. FRP has a significantly lower installation cost due to its lightweight, which reduces its labor and equipment needs when compared to steel.

Weight – There’s no doubt that steel is heavy. In fact, it can weigh up to 75% more than FRP. This means special equipment, special tools, and more labor. Often, special safety personnel have to be hired when installing steel. FRP on the other hand is lightweight, easy to install, and only requires normal tools.

Maintenance – FRP is naturally corrosion and UV-resistant. Because it doesn’t warp or crack, it requires little to no maintenance. FRP data center generator platforms will last as long as the generators themselves. Steel will need to be galvanized to be resistant to corrosion but can still corrode over time and will have to have a coating reapplied in the future. This increases steel’s long-term maintenance cost.

Electrical Conductivity – Steel is a good conductor of electricity. This poses a safety risk when working around generators and trying to minimize hazards. It adds an extra step to the installation process because the steel platforms have to be properly grounded to prevent electrical hazards. FRP is naturally non-conductive and insulates against electrical currents, increasing safety for workers.

When it comes to data center generator platforms, FRP and fiberglass come out on top every time. While steel has been the traditional material, FRP brings more benefits and cost savings. Learn more about FRP generator platforms and how DEFI can customize FRP products to fit your needs by contacting us here or check out our resources page here.

Follow us on LinkedIn!