At DEFI Fiberglass we specialize in custom fiberglass fabrication to suit any industry or application. We can manufacture FRP product according to any specifications you require. Our products are corrosion-resistant, flame retardant, non-conductive, and offer superior strength-to-weight ratio vs. steel.

CASE STUDY: MANUFACTURING PLANT REQUEST

In this video, our custom fiberglass fabrication team at our Lafayette facility is hard at work on a custom job. Our client, a manufacturer, needed a platform for their facility, and they needed it fast. However, the platform this manufacturing plant needed was not just a stock piece we ship out to be assembled on site. This client was short on time and needed the platform shipped pre-assembled, ready to use and needed to be portable.

Many fiberglass fabrication companies would shy away from custom jobs like this with short turnaround times. At DEFI, that is what we specialize in—the impossible.

The Project

As mentioned, this project was very time-sensitive with special specifications that many companies won’t accommodate. We gladly took on this project with a very quick turnaround time because we knew we could deliver.

This was for a movable platform that was to be used in a manufacturing plant to enable access to various cells. The client also wanted the platformed shipped assembled and ready to be put in service upon arrival. Again, another service many fiberglass manufacturers won’t accommodate—but we do.

The Materials

Since the client needed this platform to be corrosion resistant, we used a vinyl ester resin for its corrosion-resistant features. Vinyl ester resin is essentially a hybrid mix of polyester and epoxy resins. This results in its material properties as well as pricing fall right in the middle of the two.

- Vinyl ester is formulated to maximum corrosion resistance against most petroleum products, vapors, and corrosive chemicals

- It’s extremely heat resistant and blended for additional durability

- The impact strength is phenomenal and tensile strength rivals steel on a strength-to-weight ratio.

- Vinyl ester has fewer openings in its molecular structure, making it far more resistant to water penetration. Water penetration, also known as hydrolysis can cause damage through osmotic blistering.

- Vinyl ester’s cross bonding is more effective than polyester. This translates into vinyl ester having less chance of delamination. Additionally, vinyl esters are less sensitive to temperature and humidity.

Because the platform needed to be movable, six-inch rubber casters were added to facilitate easy portability. The choice to go with rubber over metal wheels was also a consideration of the corrosive environment.

Fast And Accurate Fiberglass Fabrication

Our fabrication team had very little time to complete this FRP platform but again, it’s what we specialize in. They began naturally buy building the support structure using the vinyl ester support beams secured with strong 316 stainless steel hardware. The six-inch rubber casters were fastened to the bottom legs using square stabilizing plates and stainless-steel hardware as well.

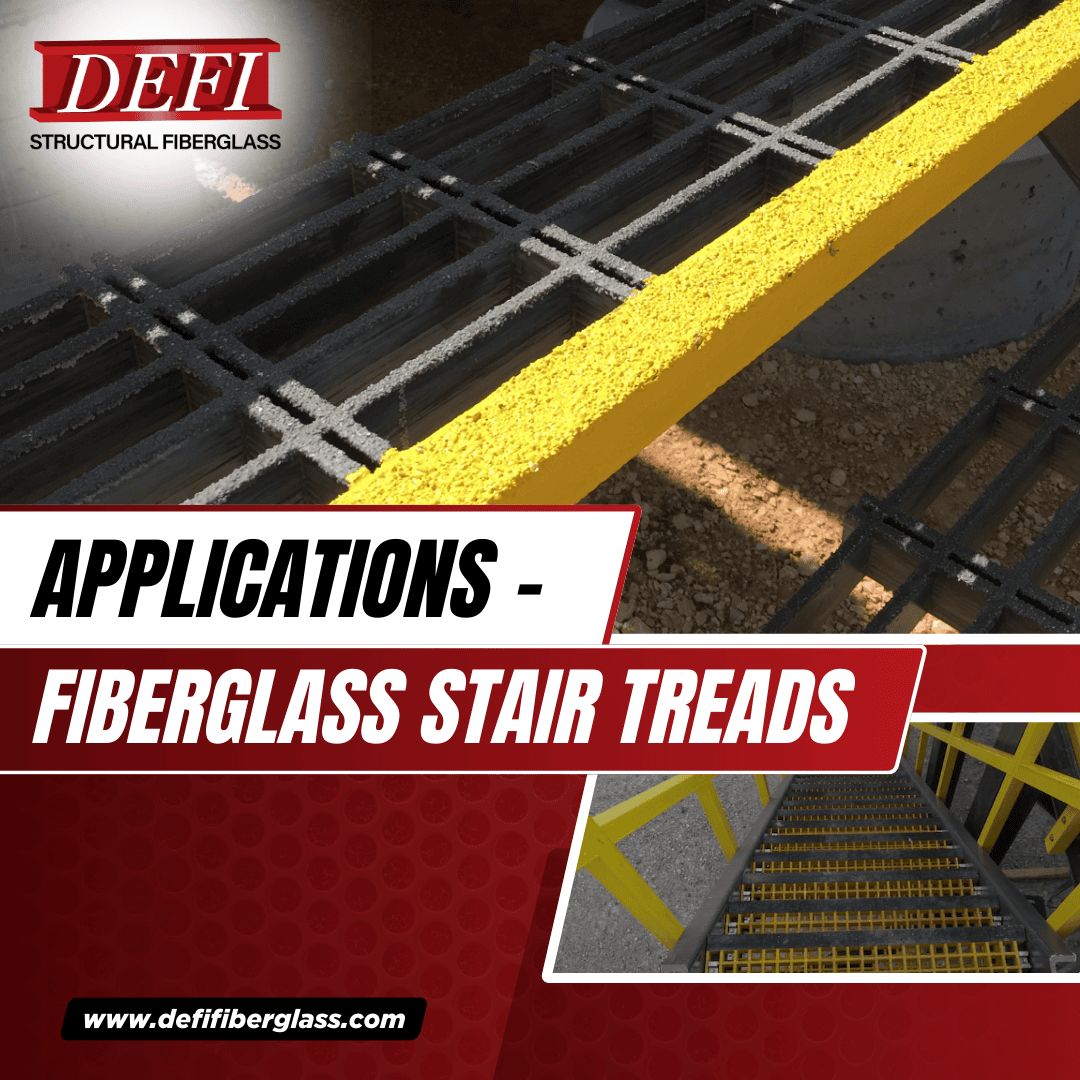

The FRP grating was then poured and cut to size (not shown in video) and bolted to the top for secure positioning and optimal load distribution. The final piece was the one-sided railing for maneuverability and fall hazard prevention.

The entire build was completed and checked thoroughly for quality standards in just 1.5 hours! This allowed us to crate and ship to the client ahead of the scheduled guarantee date. It was delivered from our Lafayette plant, ready to use as requested and was perfect for what they needed.

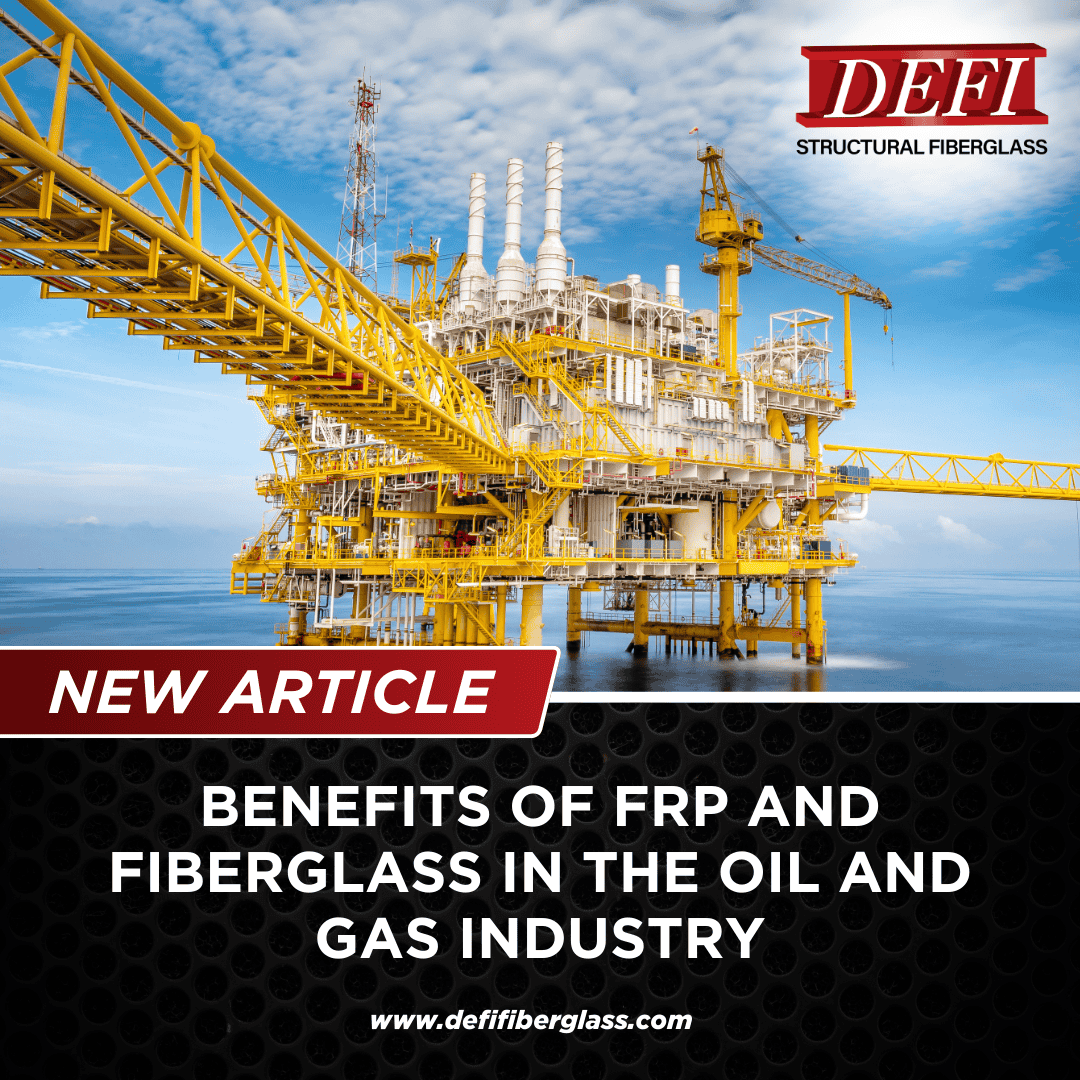

THE INDUSTRIAL ADVANTAGE OF FIBERGLASS REINFORCED PLASTIC

The unique properties of FRP make it advantageous for a wide range of industrial applications versus metal and wood. Fiberglass (FRP) is also created specifically to serve in a range of harsh and corrosive environments that other materials cannot withstand. This, in turn, saves money, time, and maintenance costs as FRP requires virtually no maintenance—it just performs.

The durability, ability to withstand corrosive agents, high temperatures, and remain non-conductive with strength on par with steel make FRP very popular. When you factor in its low cost, ease of installation, and longevity—custom fiberglass fabrication makes sense for any industry.

Limitless Applications Of Custom Fiberglass Fabrication

DEFI custom fiberglass fabrication allows you to create solutions for your business that would be very hard with other materials. Some of the most common industrial applications we have fabricated encompass a wide range of industries.

Aerospace: FRP has grown into the material of choice in the aerospace industry due to its incredible strength-to-weight ratio. The flame-resistant traits of FRP also solidify it as a choice material for aerospace flooring and platforms.

Architectural Solutions: Architectural designs are always changing and the demand for durable, lightweight construction materials is booming. Fiberglass grating, decking, landscape accents and more are perfect for the residential as well as commercial developers.

Pedestrian Bridges and Tunnels: FRP is very effective when building pedestrian bridges and tunnels. For example—many cities are incorporating FRP products along their nature and walking trails. FRP bridges and tunnels are light but extremely tough and can handle the constant load and prevent accidents.

Construction Equipment: FRP in construction equipment has evolved way past flooring and platforms. New applications we are fabricating for include structural shapes, handrails, non-conductive utility boxes and more.

Cooling Towers: With the push to go “green” for many companies and in some states, mandated—FRP is perfect for aging cooling towers. Cooling towers aide in water resource recycling and DEFI’s fiberglass products help in that process.

Oil & Gas: FRP really shines in the oil & gas industry with durable materials for rigging, flooring, ladders and more. Fiberglass flooring from DEFI is tough and can take abuse from anything from fires to saltwater and other corrosives.

WHAT CAN WE DO FOR YOU?

In fact, our custom fiberglass fabrication is perfect for any industrial application. You just bring us your needs and ideas—and we deliver the solutions. We work with our knowledge of FRP and its qualities and combine it with the knowledge you have of your industry needs. We then combine the two to create solutions that save your money, increase efficiency, and promote safety.

With over two decades of combined experience in structural fiberglass, we have the knowledge and facilities to help your company succeed and remain safe.

Contact us today and see what solutions we can create for you!