A: Fiberglass is used in all types of waterparks—mainly because they have to treat the water with chlorine, so the water is very corrosive. Fiberglass is used for access towers for areas of egress, it’s also used for sump covers. Even in general public areas as well where there are features that are ADA compliant. FRP allows for small openings and also for a special grit surface that’s good for the bottom surface of feet and toes.

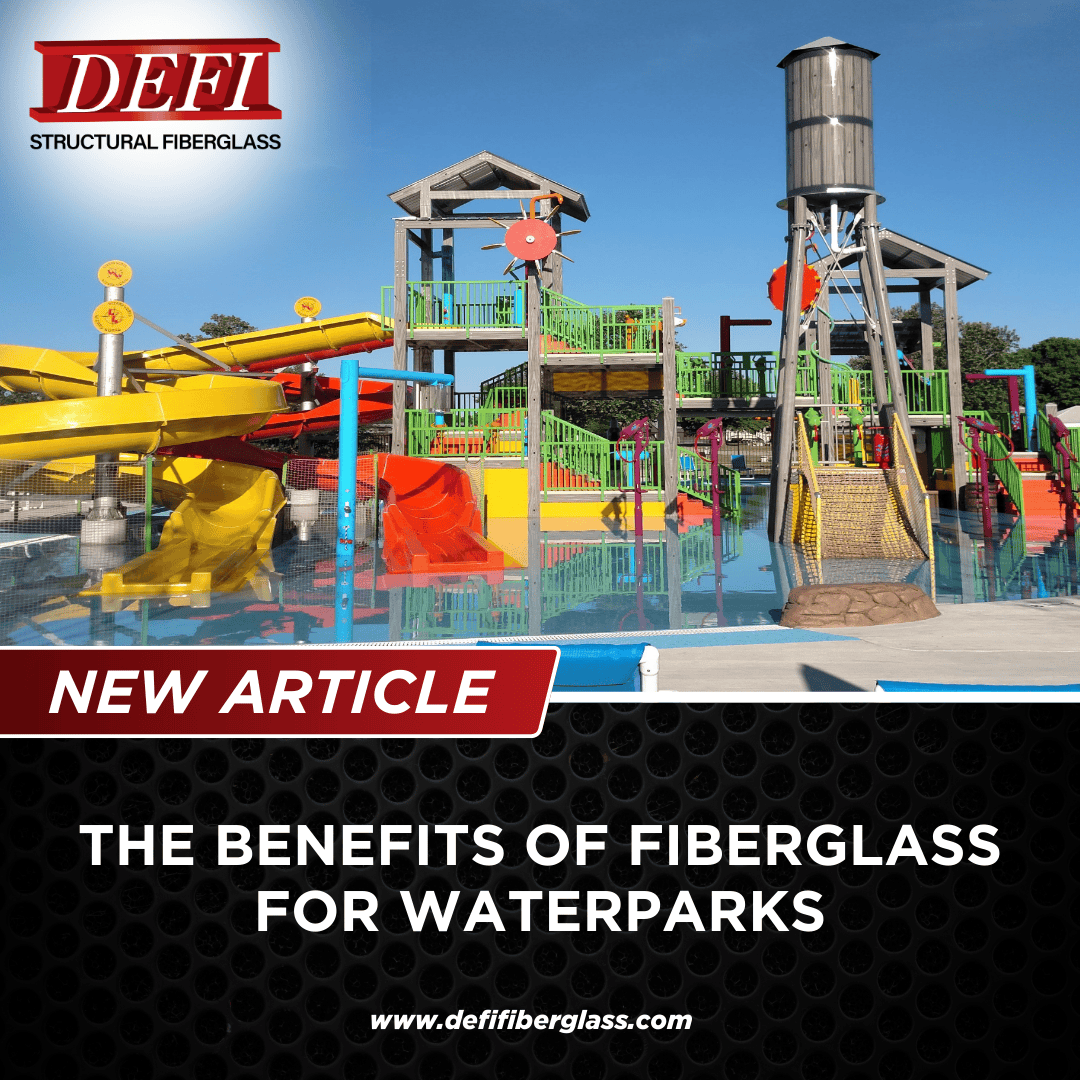

Who doesn’t love going to waterparks? Whether it’s the thrill of the latest daredevil slide or the relaxing lazy river—America loves waterparks. Maintaining a waterpark in and of itself is a huge undertaking though. There are so many wear and tear components, so many potential health hazards, and many anti-microbial challenges.

Most waterparks make extensive use of structural fiberglass and composites throughout the entire park. From the picnic areas to the concession stands, from the slides to the changing rooms—fiberglass is found everywhere and for good reason.

REASONS WHY WATERPARKS RELY SO HEAVILY ON FRP

Fiberglass, even outside of waterparks is turning into a common option among building materials. While many industries have been slower to invest in fiberglass—waterparks embraced it wholeheartedly early on. When you look at a case study of waterparks using fiberglass in their construction—you can understand why. In all honesty, without fiberglass components, waterparks would be losing money left and right on repairs.

Think about it— metal and wood handrails, decking, walkways, and trench drains in an environment with 100% exposure to water? We’re talking rampant wood rot, constant rust, and corrosion of metal. That’s not just a wear and tear issue, that could be a serious or fatal accident waiting to happen.

First, to understand why fiberglass doesn’t suffer those same fates you need to understand what it is. Now, if you’ve visited our page at least a couple of times, you’ve probably heard this a dozen times, so you can skip ahead. However, if you are new to fiberglass you need to keep reading, this may save your business some money.

Fiberglass, also known as FRP (fiber reinforced plastic) is a composite that is created from a mix of glass fibers and resin. Each component plays its part—glass fibers give fiberglass its strength, while resin offers several characteristics. The most important of these characteristics is that it’s non-conductive and corrosion-resistant, but there are others. So, in addition to the resin adding strength, it’s other properties make it widely popular for many applications. Industries such as oil & gas, energy companies, coastal municipalities, chemical plants, and of course—waterparks choose fiberglass because of:

Load Capacity

Not only is fiberglass resistant to chlorine and other chemicals corrosiveness but it can handle consistent extreme load capacities. This is perfect for waterparks in the usage of pavilion decking, trench grates, and stairs for slide towers. Metal grates, stairs, and decking not only gets extremely hot in the sun but also cannot handle impact like fiberglass can. Fiberglass is so strong that it can easily withstand fully loaded forklifts running on 12” wide FRP grating all day. Not bad at all for grating that can be carried without heavy-duty equipment and is installed with standard hand tools.

Cost Efficiency

It’s a fact, pound for pound fiberglass grating costs less than iron or steel in the long run. Also, from a job-site sense—fiberglass has a very low scrap value compared to metal. Why do we mention that? Well, when is the last time you’ve heard of a fiberglass theft problem at construction sites? Never? Exactly—because it doesn’t happen, unlike steel and iron which gets stolen all the time. So, if you’re expanding or building a new waterpark, that’s one less thing to worry about at the build site. Another thing to consider is that it’s also low-cost on the installation, as the FRP is not labor-intensive at all.

Corrosion Resistance

Fiberglass bests metal in waterparks because it cannot be damaged by corrosives such as chlorine, borax, saltwater systems, and muriatic acid. It also won’t stain from algae buildup like iron or galvanized steel does. For waterparks, due to the constant exposure to sunlight—all you need is fiberglass made with vinyl ester resin. This resin can withstand constant exposure to high-temperatures and still last up to 25 years. Compare that to metal which is lucky to last half as long in a waterpark environment.

Conductivity

Fiberglass is non-conductive. In an environment exposed to the elements with patrons that are usually water-soaked—this is crucial. Standard safety protocols at every waterpark are to exit the water and ride structures when there’s lightning. However, although rare, it has happened that lightning has struck access towers during a storm. In those rare instances, it is better to err on the side of caution and build those towers with fiberglass. Grating and decking is also a possible risk for electric shock during storms, FRP mitigates this risk.

Here’s another thing people don’t think about—corrosion between galvanized grating and stainless steel. Yes, the two metals when in contact with each other and water such as in fittings to secure grating, will corrode. This kind of electrical reaction happens anytime two different metals touch in the presence of water as well. Fiberglass avoids that issue altogether due to its lack of conductivity.

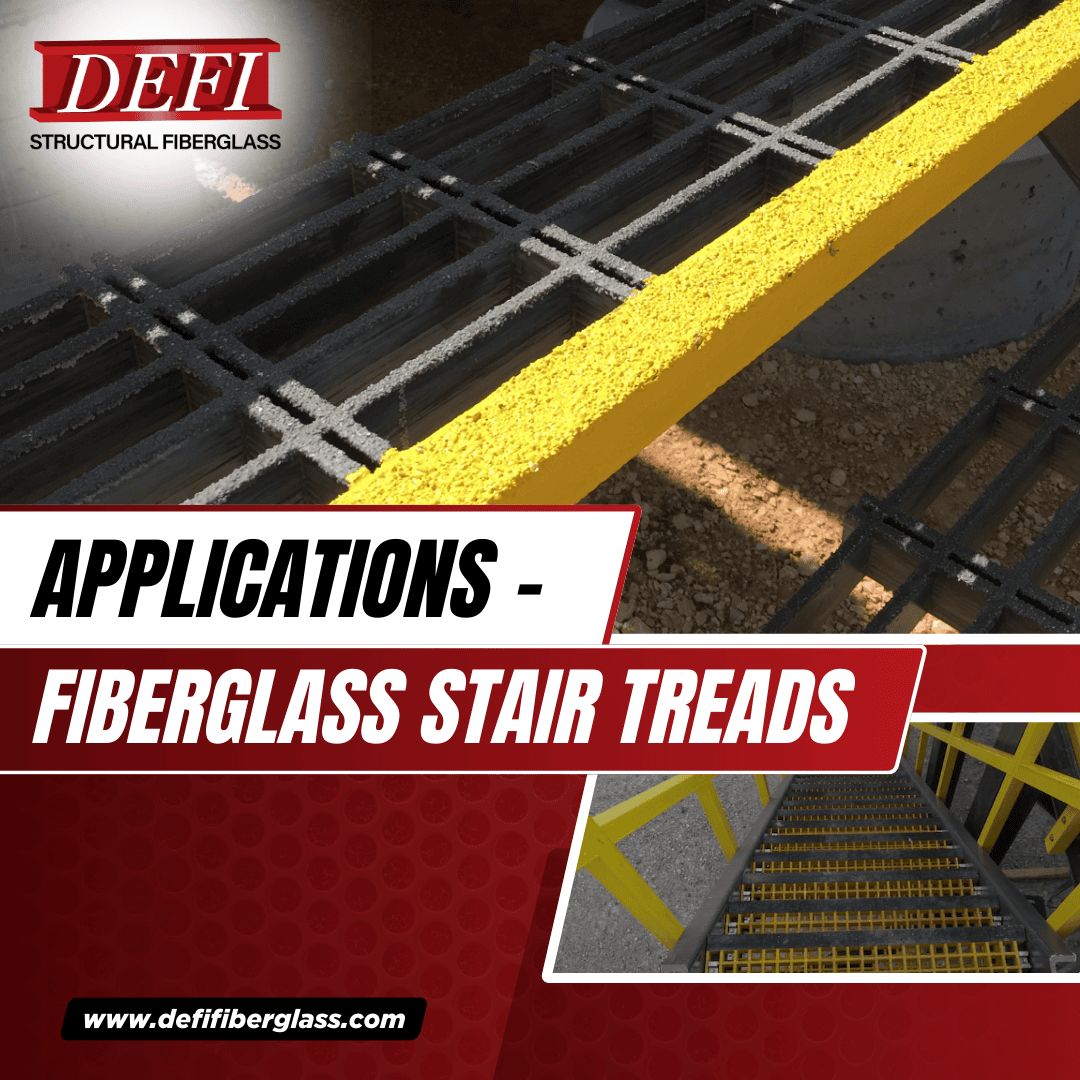

Anti-Slip Properties

Fiberglass grating can come in a smooth finish or can have special surface textures built-in during production. Grit textures are ideal for waterparks where water and bare feet can create a fall hazard due to slipping. The grit size can be adjusted based on applications such as coarse which is aggressive for gripping shoes. It can also be done in a fine grit selection that offers the same safety but is gentle on bare feet.

Versatility

FRP is perfect for a light, easy to handle, anti-slip surface in any area of a waterpark, not just decking or stairs. In fact, waterparks even use fiberglass in the restrooms, as trench gate coverings, and even grip pads on pool surfaces. Smooth fiberglass can be used as architectural pieces as well such as pool cabana sunscreens. Of course, you already know over 90% of waterpark attractions such as slides are made from fiberglass. In all honesty, there aren’t many limits to what this amazing material can be used for.

WHAT ARE WATERPARKS USING FRP FOR?

Waterparks increase their revenue in two ways—boosting attendance or raising admission prices. However, without quality attractions and low maintenance costs, it’s hard to boost attendance, let alone raise prices.

A waterpark with no special rides such as flumes, extreme slides, cascades, and sufficient picnic and leisure areas will fail. For example, a park with limited rides and no real family or kids area will lose business to a park such as Splashtown.

The hard part about that is that costs add up to provide these features with traditional materials and then there’s the maintenance. Components such as picnic tables, covered cabanas, access towers, and kid’s play areas are expensive. Of course, that is when you are building from metal, but most waterparks these days use fiberglass for:

- Water Forts

- Cascades

- Pavillion Sunscreens

- Picnic Tables

- Tanning Decks

- Locker Rooms

- Connecting Bridges

- Access Towers

In fact, it’s a fair estimate to put out there that 90% of the key structures at waterparks use fiberglass. With no corrosion worries, risk-mitigating anti-slip surfaces, and low-cost installations it just makes sense.

GET THE BEST IN STRUCTURAL FIBERGLASS WITH DEFI

Whether you’re needing FRP grating, stairs, or any other structure for waterparks, marinas, and more—we have you covered. With our seasoned consultant’s help, we can come up with a solution that suits your needs. Contact us today!