When you think of construction and creating stronger buildings, do you think of fiberglass? This sought-after material reinforces concrete, insulates homes, and forms structural components. But to maximize its benefits, you need to know how to use it.

When you think of construction and creating stronger buildings, do you think of fiberglass? This sought-after material reinforces concrete, insulates homes, and forms structural components. But to maximize its benefits, you need to know how to use it.

Your project’s durability and strength depend on it. Luckily, we’ve got you covered. In this article, we’ll explore how to use fiberglass in construction.

From practical tips to expert tricks, you’ll learn everything you need to make your next project a success. Keep reading to discover the power of FRP products.

What Is Fiberglass?

Fiberglass is a composite material made of fine glass fibers. These fibers are silica-based materials, such as glass or quartz.

They form strands that are woven or knitted into a sheet or mat. Then, a resin, usually polyester or epoxy, is combined with the sheet or mat to create a solid and robust material.

Fiberglass is famous for its strength, versatility, and durability. It’s prevalent in several applications, such as:

- Boat building

- Aircraft construction

- Automotive repairs

- Home insulation

How to Use Fiberglass

The construction industry is undergoing a revolution with FRP, also known as Fiber Reinforced Polymer. Structural fiberglass, a versatile material, is widely used in many applications.

It provides builders with lightweight, high-strength, and durable materials. This creates stronger, more resilient, and longer-lasting structures.

Reinforcing Concrete Structures

Builders reinforce concrete structures to improve their strength and durability during construction. Harsh environmental conditions, wear and tear, and heavy loads can cause concrete structures to crack or collapse. Fiberglass products have become a go-to option for builders to reinforce concrete structures.

Strengthening Wooden Structures

Builders often use wooden structures in construction due to their affordability, appealing looks, and ease of construction. However, these structures are prone to decay, insect infestation, and fire damage. To address these concerns, builders utilize FRP products to boost their durability and strength.

FRP products can reinforce wooden structures in different ways. For instance, builders use FRP wraps to strengthen wooden columns or beams. The wraps consist of multiple FRP sheets that you wrap around the columns or beams. This process enhances their load-bearing capacity.

Moreover, builders also use FRP laminates to strengthen wooden surfaces exposed to heavy loads or impact. The laminates consist of several layers of FRP sheets attached to the wooden surface using adhesive.

Seismic Retrofitting

Builders use seismic retrofitting to enhance the resistance of structures to earthquakes. Earthquakes can cause significant damage to structures, leading to loss of life and property. FRP products are perfect for seismic retrofitting due to their lightweight and high strength.

Builders can use FRP products for seismic retrofitting in various ways. For example, FRP wraps can increase the seismic resistance of concrete columns and beams. They wrap the columns or beams’ surface to enhance their strength and ductility.

FRP laminates are also useful in reinforcing walls and floors. They bond the laminates to the surfaces using adhesive, enhancing their strength and stiffness. FRP products can retrofit existing structures without adding significant weight, which is crucial for seismic retrofitting.

Bridge Rehabilitation

Bridges are critical infrastructure that connects people, goods, and services. They are subject to various forms of damage due to environmental and human factors. To maintain the safety and functionality of bridges, builders use FRP products for rehabilitation.

FRP products can serve many purposes in bridge rehabilitation, such as:

- Strengthening the decks

- Repairing the concrete

- Protecting the steel elements from corrosion

FRP products are also ideal for bridge rehabilitation due to their lightweight and high strength.

Decks

FRP decks can replace the existing bridge decks that have reached the end of their lifespan. They are:

- Lightweight

- Easy to install

- Have excellent durability and resistance to corrosion

They also have a high load-bearing capacity, which enhances the functionality and safety of the bridge.

Wraps

FRP wraps can rehabilitate the concrete columns and beams of bridges. Applying the wraps to the surface of the columns and beams increases their load-bearing capacity and flexibility. They are also easy to install and require minimal maintenance.

Used Worldwide

Builders worldwide use FRP products for bridge rehabilitation projects. For instance, in the USA, FRP decks replaced the pedestrian bridge’s existing decks. In Norway, FRP wraps rehabilitated the concrete beams of a road bridge.

Benefits

Using FRP products for bridge rehabilitation has many benefits. FRP products are lightweight, which reduces the installation time and cost. They also have excellent durability and resistance to corrosion, which increases the longevity of the bridges. They can be easily customized to fit the specific needs of the project.

Building Façade Restoration

The façade of a building is the outer shell that protects the building from environmental elements. Building facades can become damaged due to weather, pollution, or other factors. To restore the appearance and functionality of building facades, builders use FRP products.

They are ideal for building façade restoration due to their lightweight and high strength. They can serve various purposes, such as:

- Repairing cracks

- Replacing damaged panels

- Strengthening the façade elements

Replace Damaged Panels

They can replace the damaged panels of the building façade. The panels are lightweight and easy to install. This reduces the installation time and cost. They also have excellent durability and resistance to weather and pollution. This increases the longevity of the building façade.

You can also use them to repair cracks and reinforce the façade elements. The wraps are applied to the surface of the façade elements to increase their strength and ductility. They are also easy to install and require minimal maintenance.

Worldwide use

FRP products fixed many building facades globally. In Canada, they replaced broken panels of a heritage building. In the UK, they strengthened the concrete facade parts of a business building with wraps.

Benefits

Using FRP products for building façade restoration has many benefits. They are lightweight and easy to handle, reducing installation time and cost.

They also have excellent resistance to weather and pollution, which increases the longevity of the building façade. You can customize them to fit the project’s specific needs.

Fiberglass Shapes and Fiberglass Grating

Fiberglass has many uses beyond boats, planes, and house insulation. It can form shapes and grids for diverse applications.

Fiberglass shapes refer to customized parts made from fiberglass, such as:

- Tubes

- Rods

- Channels

- Angles

- Beams

These shapes are lightweight, strong, and durable. They are an ideal alternative to traditional building materials such as wood, metal, and concrete.

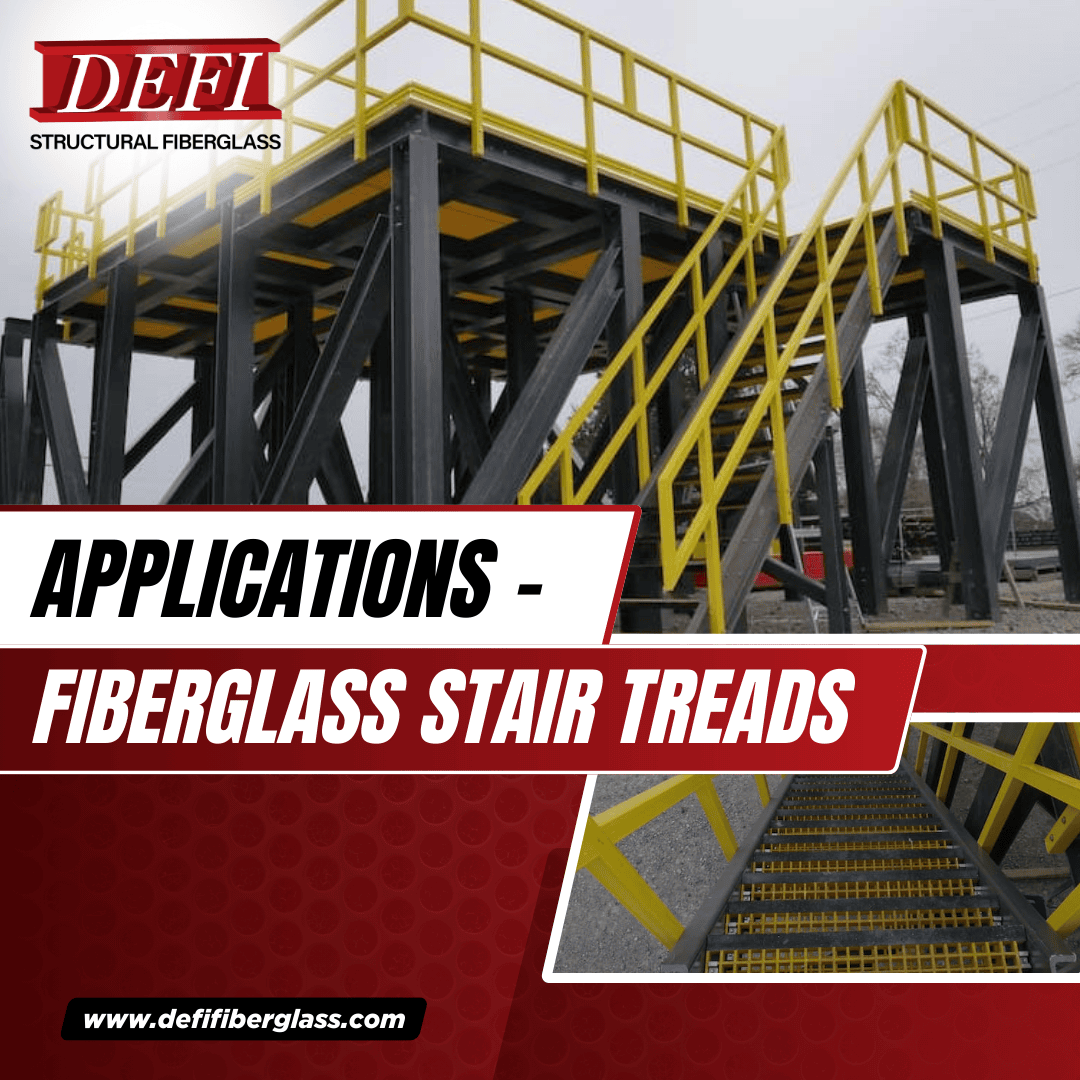

Fiberglass Grating

Fiberglass grating is a type of flooring material made from molded fiberglass-reinforced plastic. It comprises a grid-like pattern of interlocking bars or panels. It is ideal for use where slip resistance is essential, such as in wet or oily conditions.

They are also:

- Corrosion – Resistant

- Fire-retardant

- Low maintenance

It is a great choice for industrial and commercial applications such as walkways, platforms, and stair treads.

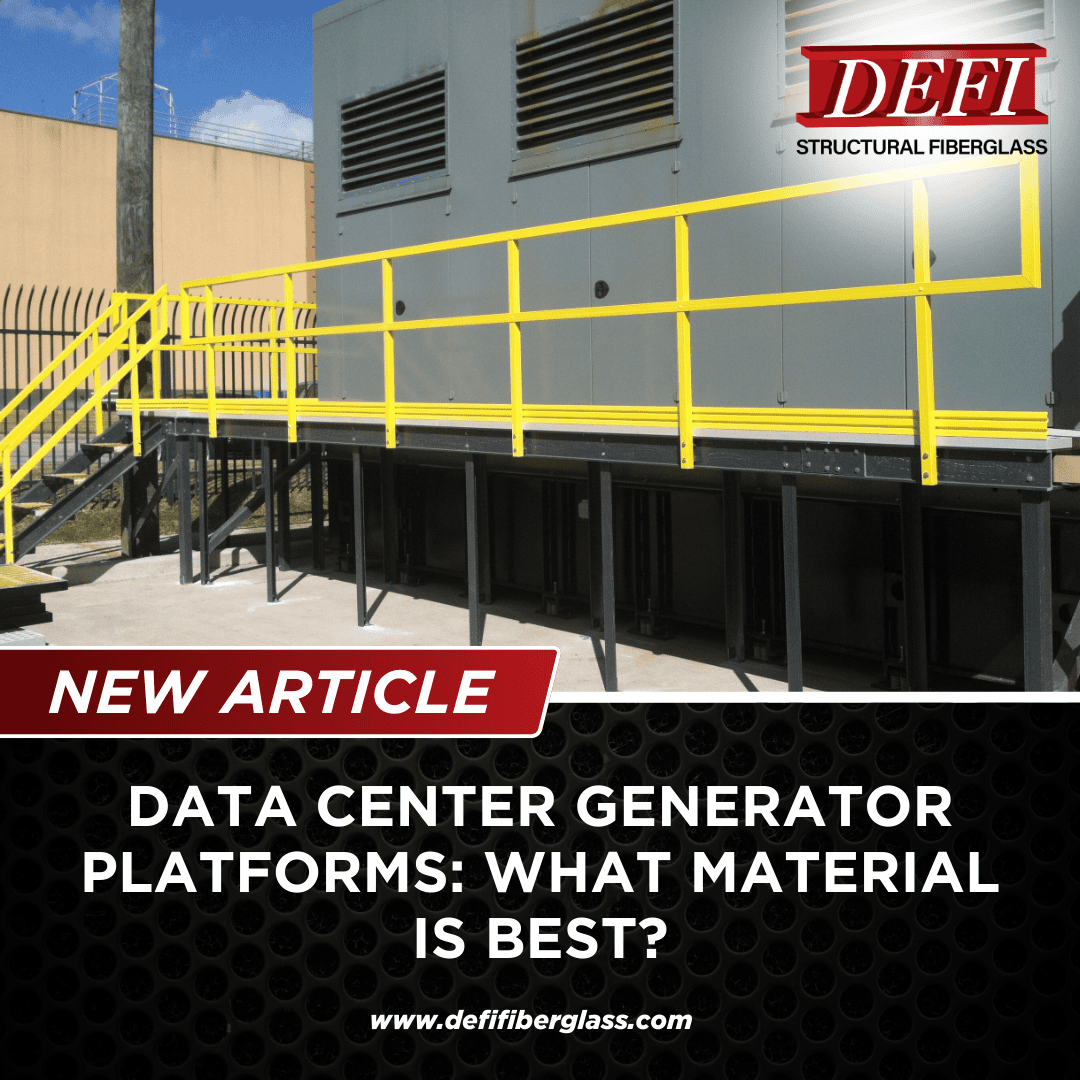

Building Stronger with DEFI

Knowing how to use fiberglass and FRP products can be a game-changer in the construction industry. FRP products provide builders with lightweight, durable, high-strength materials. It is ideal for a wide range of applications.

If you’re looking for a reliable supplier of FRP products, DEFI Structural Fiberglass can help. Contact us today to learn more about how we can help you with your next project.